Pressure Sensors

Precision Monitoring for Optimal System Performance

Key Benefits of CAMT’s Pressure Sensors

Accurate Pressure Monitoring for Enhanced System Efficiency

Precise pressure measurement is essential for optimizing fuel injection, turbocharger performance, and emission control systems. CAMT’s advanced sensor technology ensures:

- High-Precision Pressure Sensing – Delivers real-time monitoring of fuel, air, and exhaust pressure to optimize performance and emissions control.

- Enhanced Fuel Economy – Supports efficient fuel atomization and combustion, reducing fuel waste.

- Optimized Turbo & Exhaust Management – Ensures precise boost pressure regulation, enhancing engine responsiveness and longevity.

By providing reliable pressure data, CAMT’s sensors help optimize combustion efficiency, reduce emissions, and improve overall vehicle performance.

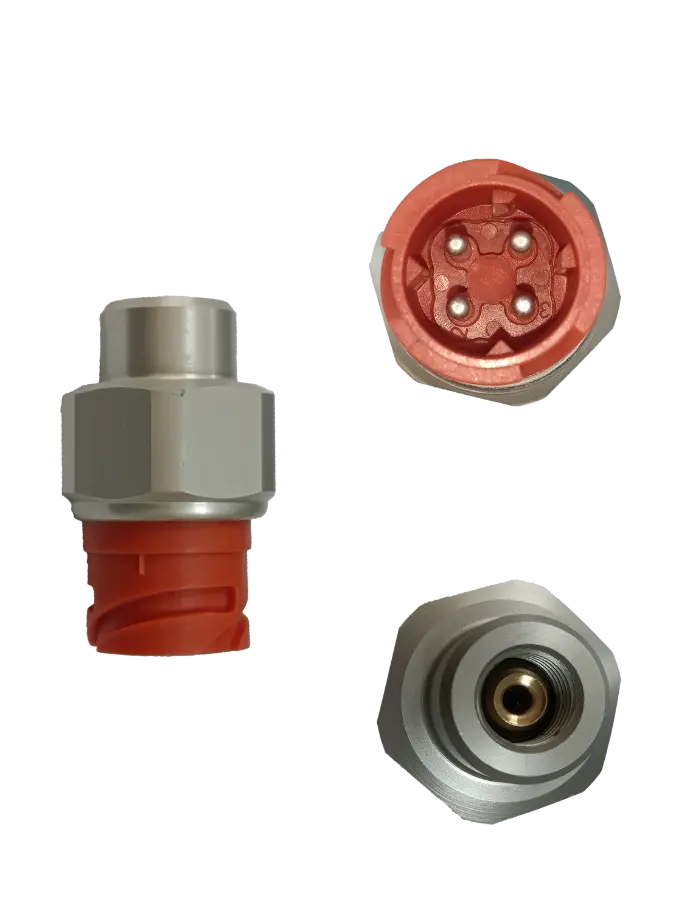

Built for Harsh Environments & Long-Term Reliability

Pressure sensors must withstand extreme operating conditions, including high temperatures, vibration, and exposure to fuel and oil contaminants. CAMT’s sensors are built with:

- High-Temperature Resistance – Designed for continuous operation in hot engine environments without performance degradation.

- Corrosion-Resistant Materials – Constructed with advanced alloys and protective coatings to resist fuel, oil, and chemical exposure.

- Sealed & Ruggedized Design – Built for high-pressure endurance, ensuring reliable operation under extreme loads.

By utilizing robust materials and precision engineering, CAMT’s Pressure Sensors provide long-lasting durability with minimal maintenance requirements.

Compliant with Global Industry Standards

As emissions and efficiency regulations become increasingly stringent, CAMT’s Pressure Sensors ensure compliance with:

- Euro 6 & Euro 7 Emissions Standards – Supports efficient engine calibration for reduced emissions.

- EPA Regulations – Meets North American fuel system pressure monitoring requirements.

- IATF 16949 Certified Manufacturing – Adheres to strict global quality management standards, ensuring reliability and consistency.

- OEM-Approved Specifications – Designed to integrate seamlessly with fuel, air, and exhaust pressure monitoring systems.

By complying with industry-leading regulations, CAMT’s sensors help manufacturers and fleet operators maintain emissions control and fuel efficiency.

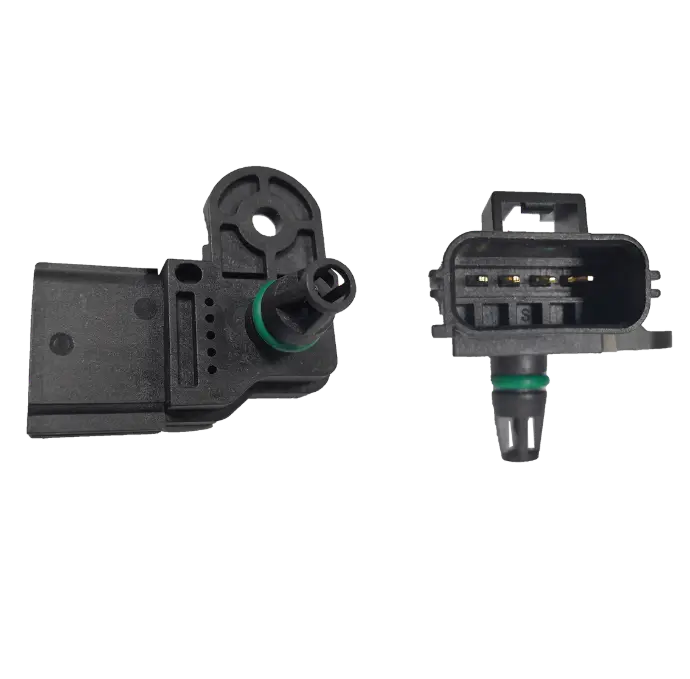

Versatile Applications Across Automotive & Industrial Systems

CAMT’s high-precision Pressure Sensors are designed for a wide range of automotive and industrial applications, including:

- Fuel System Pressure Monitoring – Ensures consistent fuel injection pressure, optimizing combustion efficiency and emissions control.

- Turbocharger & Boost Pressure Regulation – Provides accurate turbo pressure feedback, enhancing power delivery and responsiveness.

- Exhaust Gas Pressure Monitoring – Supports DPF and EGR system management, helping prevent excessive soot buildup.

- Hydraulic & Pneumatic Systems – Delivers precise pressure readings for braking, suspension, and cooling systems.

With adaptable configurations, CAMT’s Pressure Sensors are an ideal solution for modern vehicles and industrial machinery.

Seamless OEM Integration & Intelligent Design

CAMT’s next-generation Pressure Sensors are designed for effortless integration into modern engine control, fuel management, and emissions systems.

- Fast Response Time & High Sensitivity – Provides instantaneous pressure feedback, improving system efficiency.

- Standardized Electrical Interfaces – Supports CAN, LIN, and SPI communication protocols for easy ECU connectivity.

- Compact & Lightweight Design – Minimizes system complexity, making installation simple.

- Long-Term Stability & Minimal Drift – Maintains accurate readings over extended operation, reducing recalibration needs.

With plug-and-play compatibility, CAMT’s sensors deliver seamless performance across OEM and aftermarket applications.

Advanced Sensor Technology for Next-Generation Vehicles

Why Choose CAMT Pressure Sensors?

Precision Monitoring for Engine & Fuel Systems

Delivers real-time pressure data, improving engine efficiency and emissions control.

Rugged & Reliable Design

Built to withstand extreme operating conditions, ensuring long-lasting durability.

Industry-Leading Compliance & Quality

All components of the product meet or exceed automotive-grade standards.

Optimized Fuel Efficiency & System Performance

Helps reduce fuel waste, emissions, and maintenance costs.

Trusted by OEMs & Manufacturers Worldwide

Used in 30+ countries for passenger, commercial, and industrial applications.

CAMT’s Pressure Sensors are built using state-of-the-art sensing technology, ensuring long-term accuracy, efficient system performance, and compliance with evolving industry standards.

- Innovation-Driven R&D – CAMT continuously develops new sensor technologies to improve pressure monitoring accuracy and response times.

- Automated Manufacturing & Rigorous Testing – Each sensor undergoes precision calibration and durability testing to ensure reliability.

- Extreme Condition Validation – Tested under high-temperature, pressure fluctuation, and vibration stress, ensuring consistent operation.

- OEM & Custom Solutions Available – Engineered for multiple vehicle types and industry-specific applications, with flexible configurations.

With a focus on efficiency, reliability, and precision, CAMT’s Pressure Sensors provide best-in-class monitoring solutions for modern automotive and industrial systems.