Electric Coolant Valves

Intelligent Cooling Control for Maximum Efficiency

Key Benefits of CAMT’s Electric Coolant Valves

Precision Cooling Control for Optimized Performance

Controlling coolant flow is critical for maintaining stable engine temperatures, improving energy efficiency, and reducing emissions. CAMT’s electronically controlled water valves allow for:

- Dynamic Flow Adjustment – Smart valve control optimizes coolant circulation in real time, improving heat management in combustion, hybrid, and electric powertrains.

- Efficient Temperature Regulation – Helps maintain ideal operating temperatures for engines, transmissions, and battery packs, reducing wear and improving performance.

- Reduced Energy Consumption – By directing coolant only where needed, CAMT’s valves minimize energy loss, contributing to better fuel economy and extended battery range.

These features make CAMT’s Electric Water Valves an essential component for efficient and adaptive vehicle cooling systems.

Designed for Durability & Reliability

Vehicle cooling systems operate in harsh conditions, requiring components that can withstand continuous heat cycles, vibrations, and coolant exposure. CAMT’s Electric Water Valves are engineered for long-lasting performance and minimal maintenance through:

- High-Temperature Resistance – Ensures consistent functionality in extreme conditions, from sub-zero temperatures to high-heat engine compartments.

- Sealed, Corrosion-Resistant Construction – Uses high-quality polymers and metal alloys to prevent leaks and degradation from extended coolant exposure.

- Precision Motorized Actuation – Provides smooth, accurate valve operation, minimizing system strain and extending component lifespan.

With a rigorous multi-stage testing process, CAMT’s Electric Water Valves are built for long-term reliability in demanding applications.

Compliant with Global Industry Standards

Regulatory compliance for thermal management and emissions reduction requires advanced, electronically controlled cooling solutions. CAMT’s Electric Water Valves meet and exceed:

- IATF 16949 Certified Manufacturing – Produced under strict global quality control standards, ensuring consistency, reliability, and durability.

- OEM-Approved Specifications – Engineered for seamless integration with existing vehicle cooling architectures.

By meeting stringent industry regulations, CAMT’s Electric Water Valves support next-generation cooling system efficiency.

Versatile Applications Across Vehicle Types

Designed for modern automotive and industrial cooling applications, CAMT’s Electric Water Valves deliver efficient and adaptable thermal regulation in:

- Passenger & Commercial Vehicles – Provides accurate thermal management for internal combustion, hybrid, and fully electric powertrains.

- Heavy-Duty Trucks & Off-Highway Equipment – Ensures optimal engine and transmission cooling in high-performance applications.

- Electric & Hybrid Vehicle Battery Cooling – Regulates liquid cooling loops for EV batteries, extending range and enhancing performance.

- Industrial & Marine Applications – Supports precision temperature management in factory machinery, marine engines, and HVAC systems.

With intelligent flow control and adaptive performance, CAMT’s Electric Water Valves improve cooling efficiency across multiple industries.

Seamless OEM Integration

CAMT’s Electric Water Valves are designed for plug-and-play compatibility, ensuring effortless integration with modern engine cooling and HVAC systems.

- Electronic Control Compatibility – Supports PWM, CAN, and LIN protocols, allowing for real-time coolant flow adjustments.

- Compact, Lightweight Design – Reduces overall vehicle weight and system complexity, improving fuel efficiency.

- Robust Sealing & Connector Design – Guarantees secure electrical connections, preventing moisture and dirt ingress.

- Long-Term Calibration Stability – Maintains high-precision coolant regulation, reducing wear and tear on system components.

By ensuring seamless compatibility with existing OEM and aftermarket cooling solutions, CAMT’s valves enhance vehicle longevity, efficiency, and performance.

Precision Fluid Control & Next-Generation Engineering

Why Choose CAMT Electric Water Valves?

Intelligent Thermal Regulation

Smart coolant control optimizes engine and battery cooling efficiency.

High-Performance Durability

Built to withstand extreme operating conditions, ensuring long-term reliability.

Industry-Leading Standards Compliance

All components of the product meet or exceed automotive-grade standards.

Energy Efficiency & Emission Reduction

Supports better fuel economy, lower emissions, and improved electric vehicle range.

Trusted by OEMs & Manufacturers Worldwide

Used in 30+ countries across automotive and industrial applications.

CAMT’s Electric Water Valves are designed and produced using cutting-edge engineering principles and advanced testing protocols to deliver industry-leading cooling solutions.

- Innovation-Driven Development – CAMT continuously improves design, material selection, and performance capabilities to stay ahead of industry advancements.

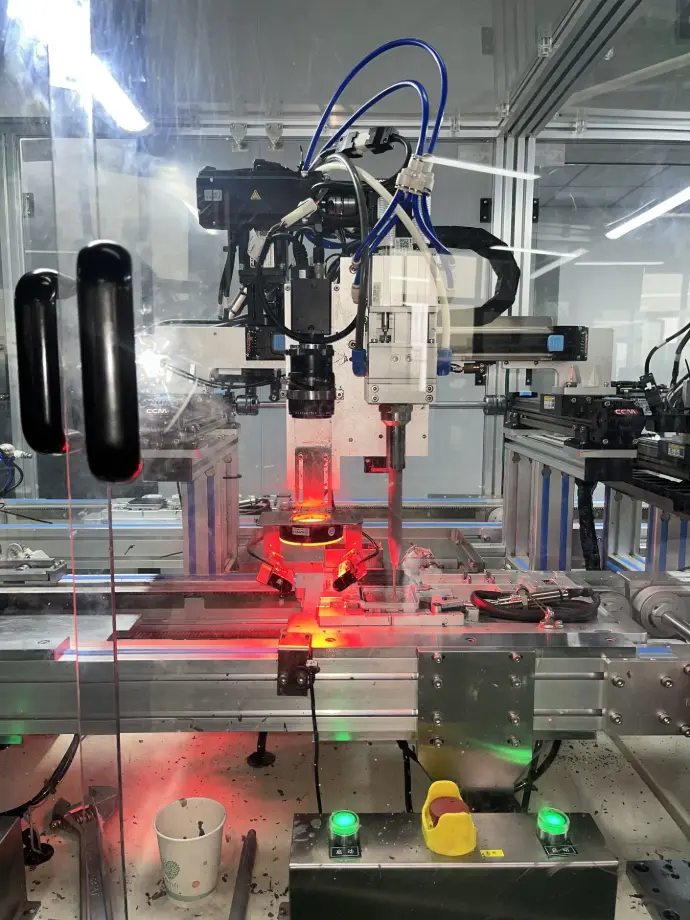

- Automated Manufacturing & Quality Assurance – Each valve undergoes precision calibration and multi-stage durability testing to ensure reliability.

- Extreme Condition Testing – Validated under high-temperature, vibration, and corrosion resistance tests, ensuring optimal long-term operation.

- OEM & Custom Solutions Available – Engineered to meet a variety of vehicle and industrial cooling requirements, with customization options for specific applications.

CAMT’s commitment to intelligent thermal management solutions ensures optimal cooling performance, extended component lifespan, and maximum efficiency for modern automotive and industrial applications.