High-Precision NOx Sensors

Engineered for Emission Control & Efficiency

Inside CAMT’s NOx Sensor Production

See How Our NOx Sensors Are Made

Discover how CAMT’s advanced automated production processes, precision engineering, and rigorous quality control come together to create high-performance NOx sensors. View our step-by-step assembly process and see why our sensors are trusted worldwide for emissions monitoring and compliance.

Key Benefits of CAMT’s NOx Sensors

Precision Engineering for Emission Control

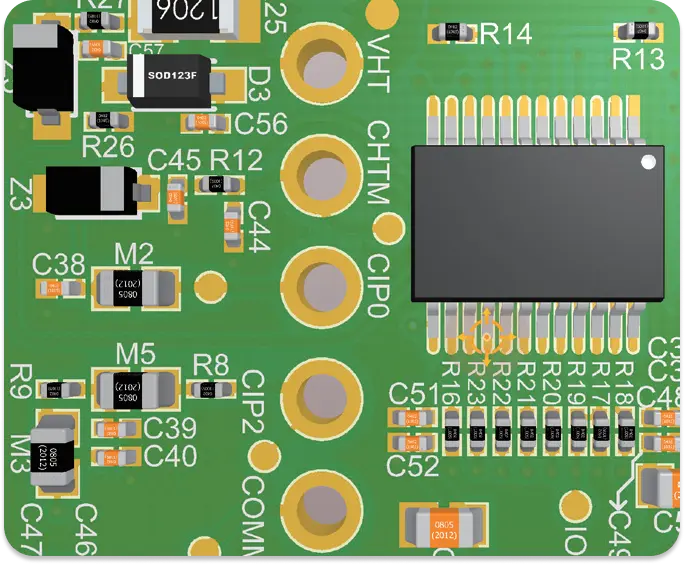

CAMT NOx sensors utilize advanced ASIC chip technology to provide accurate, real-time measurements of nitrogen oxide levels in vehicle exhaust gases.

With highly sensitive detection capabilities, our sensors provide accurate data transmission to the ECU (Engine Control Unit), enabling precise air-fuel ratio adjustments.

This level of accuracy helps reduce NOx emissions while maintaining engine efficiency, ensuring compliance with strict emission standards without sacrificing vehicle performance.

Built for Durability & Longevity

Vehicles operate under harsh environmental conditions, from extreme temperatures to continuous vibrations and exposure to corrosive exhaust gases.

CAMT NOx sensors are engineered with high-quality materials and a multi-layer PCB design, ensuring exceptional heat resistance, mechanical stability, and long-term performance.

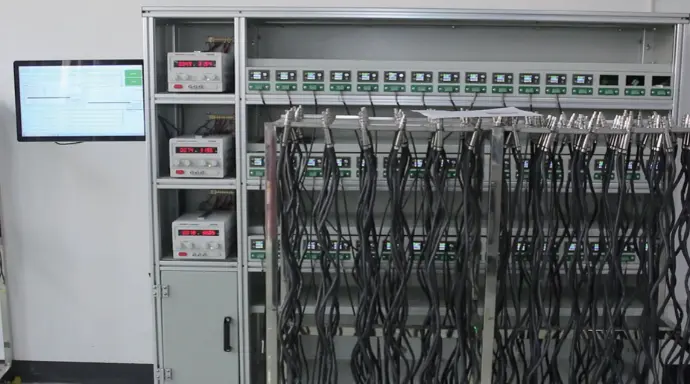

Our sensors undergo a rigorous 7-stage quality control process, including high-temperature endurance testing, water-tightness validation, and vibration resistance assessments, ensuring that each unit delivers consistent and reliable performance over an extended service life.

Compliant with Global Emission Standards

Stricter emission regulations demand advanced and precise monitoring systems. CAMT NOx sensors meet and exceed industry standards, including:

- Euro 6 Compliance – Reduces NOx emissions in accordance with European environmental policies.

- EPA Regulations – Ensures compatibility with on-road and off-road diesel engines used in heavy-duty commercial and industrial applications.

- OEM-Approved Specifications – Designed to meet the same quality and performance benchmarks as original equipment manufacturer (OEM) sensors.

By choosing CAMT’s NOx sensors, manufacturers, fleet operators, and vehicle owners can stay ahead of regulatory changes while reducing harmful environmental impact.

Wide Vehicle Compatibility

NOx emissions are a concern for multiple vehicle types, from passenger cars to heavy-duty commercial fleets and industrial machinery. CAMT NOx sensors are engineered for universal compatibility, making them a versatile solution for a broad range of applications, including:

- Passenger Vehicles – Enhances fuel efficiency and emissions control for gasoline and diesel cars.

- Commercial Trucks & Buses – Maintains optimal performance in long-haul transportation by regulating exhaust emissions.

- Construction & Off-Road Equipment – Meets regulatory requirements for heavy machinery operating in high-emission industries.

- Agricultural & Industrial Machinery – Ensures compliance with environmental standards for farm and factory equipment.

Regardless of vehicle type, CAMT NOx sensors deliver high-precision monitoring, long-term durability, and seamless integration with engine management systems.

Seamless OEM Integration

A crucial challenge in emission control is sensor compatibility with modern vehicle systems. CAMT NOx sensors are manufactured to strict OEM specifications, ensuring plug-and-play installation with existing vehicle architectures. Our sensors:

- Utilize standard communication protocols (SPI, CAN, LIN) for real-time data transmission.

- Feature robust connector designs that ensure stable electrical connections, even in high-vibration environments.

- Are engineered to work seamlessly with advanced ECU algorithms for optimal fuel combustion and exhaust treatment.

- Undergo precise calibration to minimize drift and maintain long-term measurement accuracy.

This seamless integration minimizes downtime, reduces the need for recalibration, and ensures consistent emissions monitoring without costly modifications.

Advanced Engineering & Manufacturing Excellence

Why Choose CAMT NOx Sensors?

Industry-Leading Technology

Advanced multi-layer PCB design and ASIC chips for superior performance and real-time emission control.

Rigorous Quality Control

A 7-stage testing process guarantees consistency, accuracy, and durability.

Proven Track Record

Used in 30+ countries worldwide by leading OEMs and aftermarket suppliers.

Optimised Fuel Efficiency

Helps maintain the ideal air-fuel ratio, reducing overall fuel consumption and ensuring smoother engine operation.

CAMT’s NOx sensors are developed using state-of-the-art engineering processes and cutting-edge manufacturing technology to ensure superior performance, reliability, and compliance with global emission standards.

- Research & Development Driven – CAMT invests heavily in R&D to continuously enhance sensor accuracy, durability, and integration capabilities, ensuring that our products stay ahead of evolving industry standards.

- Automated Production & Testing – Our NOx sensors are manufactured using semi-automated production lines with precision calibration and functional validation at every stage, reducing variability and ensuring consistency.

- High-Temperature and Environmental Resistance – Designed to withstand extreme heat, moisture, and vibrations, CAMT sensors are rigorously tested under real-world conditions to guarantee durability and long service life.

- Stringent Quality Control – Each unit undergoes a multi-stage inspection process, including thermal cycling, electrical performance analysis, and material integrity testing, ensuring that only the highest-quality products reach the market.

By integrating advanced engineering principles with rigorous quality assurance, CAMT delivers NOx sensors that provide reliable, long-term solutions for emission control and vehicle efficiency.